As summer days give way to fall and temperatures begin to dip, the shift in the weather affects your suspension. This time of year is often characterized by cool mornings and hot afternoons, and riders may notice equipment performance fluctuates as well. Perhaps you notice your damper or dropper post becoming sluggish? Because suspension manufacturers design equipment for a limited range of atmospheric and temperature conditions, when the baseline shifts so does performance. Standard year-round maintenance goes a long way towards minimizing those effects, but when the cold sets in, here are a few additional things to consider.

OIL VISCOSITY, AIR VOLUME & MATERIAL PLASTICITY

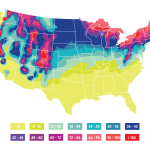

Generally, the optimized ambient temperature range for most suspension equipment is between 40º-110º Fahrenheit. Temperatures below or above these thresholds affect oil viscosity, air pressure and seal plasticity. Suspension equipment includes both hydraulic and pneumatic assemblies which are affected by temperature. In colder temperatures, oil viscosity increases, delivering greater damping force as the more viscous oil flows through the damper’s shims (valving) and piston(s). The colder the temperature, the more pronounced this effect becomes — some high performance fluids help to mitigate these fluctuations.

Air and oil contract in the cold, which affects the pressure in air-sprung and hydraulic-line-actuated parts. Coil-sprung suspensions are less affected by temperature shifts, which some riders see as an advantage. Whether you have an air- or coil-sprung product, seals may harden in cold weather and materials constrict, which increases both stiction (the static friction of the suspension before the parts slide) and friction (while the parts slide). The result is less sensitive (less plush) suspension, which in turn negatively affects traction, comfort and control.

On cold mornings or night rides, you may benefit from opening (reducing) damper settings by 2-3 clicks. Remember to double-check your sag settings prior to the start of a ride. As you ride, fluids will warm up and the ambient temperature may increase. Both changes will slowly reduce the viscosity of fluids and friction/stiction forces within your system. If the temperature swing over the course of the ride is large enough, your equipment may start to feel overly compliant and you’ll want to add back those clicks of damping. In sustained winter conditions, lighter weight fluids may be used to offset increased viscosity.

DROPPER POSTS

Dropper posts, especially hydraulically actuated products like the Rockshox Reverb react to cold weather. It’s very common for them to function sluggishly or not at all in very cold temperatures. Bleeding the hydraulic line can often resolve or prevent these symptoms, but this must be done regularly. Aftermarket upgrades can eliminate the hydraulic line altogether by converting to a cable actuator. Both Bike Yoke and Wolftooth Components make solid options. If your post allows you to add air, be sure to check and top off pressures when your equipment is cold. Remember to avoid pressure washing dropper posts and suspension components as it can force water past the wiper seal and into the lower mast assembly, where it can freeze and lock up a post (water is the enemy even in the warm months as corrosion and oil contamination may result from moisture ingress).

FAT BIKES

Winter fat bikers can benefit from lighter weight lubricants and fluids. Fat bike suspension fork options are limited, the most common being the Rockshox Bluto. The 32mm stanchions of the Bluto combined with the wide axle spacing are more susceptible to lateral twisting. A twisted chassis combined with more viscous fluids and hardened seals can make for a notchy ride quality. If you’re interested in a burlier alternative, the Manitou Mastodon uses 34mm stanchions and comes in both Expert and Pro models. The Mastodon Pro offers a more adjustable compression damper and the higher end (more sensitive) Dorado airspring.